€28.99

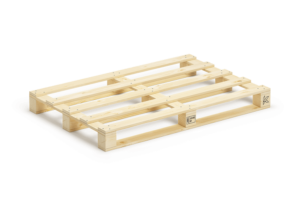

EUR pallet or EPAL pallet which is made of Swedish wood where most is spruce but also some pine is used. The wooden boards are nailed with continuous nails that are folded to eliminate the board coming loose. The full pallet can be lifted by a forklift and a pallet truck.

Feel free to supplement with pallet collar for maximum load volume.

- Capacity 1500 kg, evenly distributed

- The dimension 800 × 1200 mm was standardized throughout Europe and is called EUR.

- UIC-marked

- The pallets are IPPC approved by the Swedish Board of Agriculture.

- ISO certified 14001

- The full pallet has chip blocks

The EUR-pallet, also known as Euro-pallet or EPAL-pallet, is the standard European pallet as specified by the UIC pallet working group and the UIC 435-2 leaflet. Pallets conforming to the standardization are eligible for the European Pallet Pool (EPP), the system which allows for an exchange as “pallet for pallet”.

The EUR/EPAL-pallet is 800 mm × 1,200 mm × 144 mm (31.5 in × 47.2 in × 5.7 in); it is a four-way pallet made of wood that is nailed with 78 special nails in a prescribed pattern. The weight of a EUR/EPAL-pallet (EPAL 1) is approx. 25 kg. Around 450-500 million EUR-pallets are in circulation.

The safe working load of a EUR/EPAL-pallet is 1,500 kg. The maximum additional load can be up to 4,000 kg when stacking.

The EUR/EPAL-pallet may weigh up to 1,500 kg (3,300 lb) when equally loaded, otherwise, the limit is 1,000 kg (2,200 lb).

The Euro-pallet dates back to the wooden pallets used in railway transport. In 1961 the European railways commissioned the standardization of a common pallet type under the auspices of the UIC. The inventors were the Svensson brothers of Gyllsjö, Skåne, Sweden. Using the Euro-pallet, it was possible to load railroad cars in just 10% of the time of earlier loading processes. In 1968 the association also specified a standard lattice box along with a standard lattice box pallet.

Following the standardization most of the European industry switched over to using Euro-pallets with trucks, forklifts, and high-rack warehouses optimized for their size. National associations developed framework agreements for pallet exchange in that freight would be delivered on Euro-pallets and be given the same number of Euro-pallets in return (“pallet for pallet”). The Euro-pallets are controlled by the association and the association takes care of repairing or removing old pallets from the pool. With the ongoing European integration, the European Pallet Pool allowed for pallet exchange even in cross-border dealings.

With the success of the Euro-pallets, a number of replicas entered the market that used low-quality wood which splintered easily and were prone to mold. So the European railways, which own the trademarks for EUR/EPAL, created a separate standardization body. EPAL, the European Pallet Association e.V., was founded in 1991, and the EUR and EPAL logo may only be used by licensees of that organization. EPAL assumed responsibility for the safety and quality of all pooled pallets in 2016.

Globalization has made for a decline of the EUR/EPAL system since the EUR-pallets do not fit well into ISO containers. It is still the most widespread pallet type in the world, with an estimate of 350 to 500 million EUR-pallets being in circulation. One of the advantages is that the 800 mm (31 in) width fits through normal doors (the most common DIN door type is 850 by 2,000 mm [33 by 79 in]).

Derivatives of the EUR-pallet have been developed for specific uses. The EUR-pallet – also EUR-1-pallet – was followed by the EUR-2-pallet and EUR-3-pallet, which are both 1,200 mm × 1,000 mm (47 in × 39 in), which is close to the standard American pallet type of 40 in × 48 in (1,016 mm × 1,219 mm). For use in retail stores, the EUR-6-pallet is half the size of the EUR-pallet, 600 mm × 800 mm (24 in × 31 in). ISO standards have also been published for these Euro-pallet types.

To accommodate EUR-pallets, there are derivative intermodal containers that are about 2 in (5 cm) wider — these are commonly known as “pallet-wide” containers. These containers feature an internal width of 2,440 mm (96 in) for easy loading of two 1,200 mm (47 in) long pallets side by side – many sea shipping providers in Europe allow these, as overhangs on standard containers are sufficient to fit them in the usual interlock spaces. Especially the 45 ft (14 m) pallet-wide high-cube shortsea container has gained wide acceptance, as these containers can replace the A-Behälter swap bodies with a length of 13,670 mm (44 ft 10 in) that are common for truck transport in Europe. The EU has started a standardization for pallet-wide containerization in the EILU (European Intermodal Loading Unit) initiative.

Reviews

There are no reviews yet.